Business Hours

Monday-Friday 08:00 am to 05:00 pm

Have any Questions?

414.421.8890

- - 2019 - 2021 Doosan TT1800SY with 8-Axis including a Y-Axis Slide

- - 2014 Eurotech Elite B735SLY with 6- Axis including a YAxis Slide

- - Halter robot loading systems

- - 2013 & 2017 Doosan 2100SY with 6-Axis including a Y-Axis Slide (2)

- - Puma 2100SY II CNC Lathe

- - 2016 & 2018 Hanwha CNC SwissTurn XD38-11 Type Y (2 / up to Ø38mm)

- - 2010 & 2014 Hanwha CNC SwissTurn XD32H (2 / up to Ø35mm )

- - 2021XDi32 9-AXIS (w/B Axis) CNC Swiss-Turn (1 / up to Ø32mm)

- - 2007-2021 Hanwha CNC Swiss-Turn XD20II H (3 / up to 20mm)

- - 2008 & 2015 Hanwha CNC Swiss Turn XD32H (2 / up to 32mm)

- - 2006 Hanwha CNC Swiss-Turn SL32HPII (up to 32mm)

- - Kitamura Mycenter-2XV

- - 2024 Kitamura MyCenter HX300iG/400 High Production Horizontal Machining Center

- - 2022 Doosan 2100SY with 6-Axis, Including a Y-Axis Slide

- - CX3-2300S-V15 7.5X-45X Zoom Stereo Microscope Inspection System

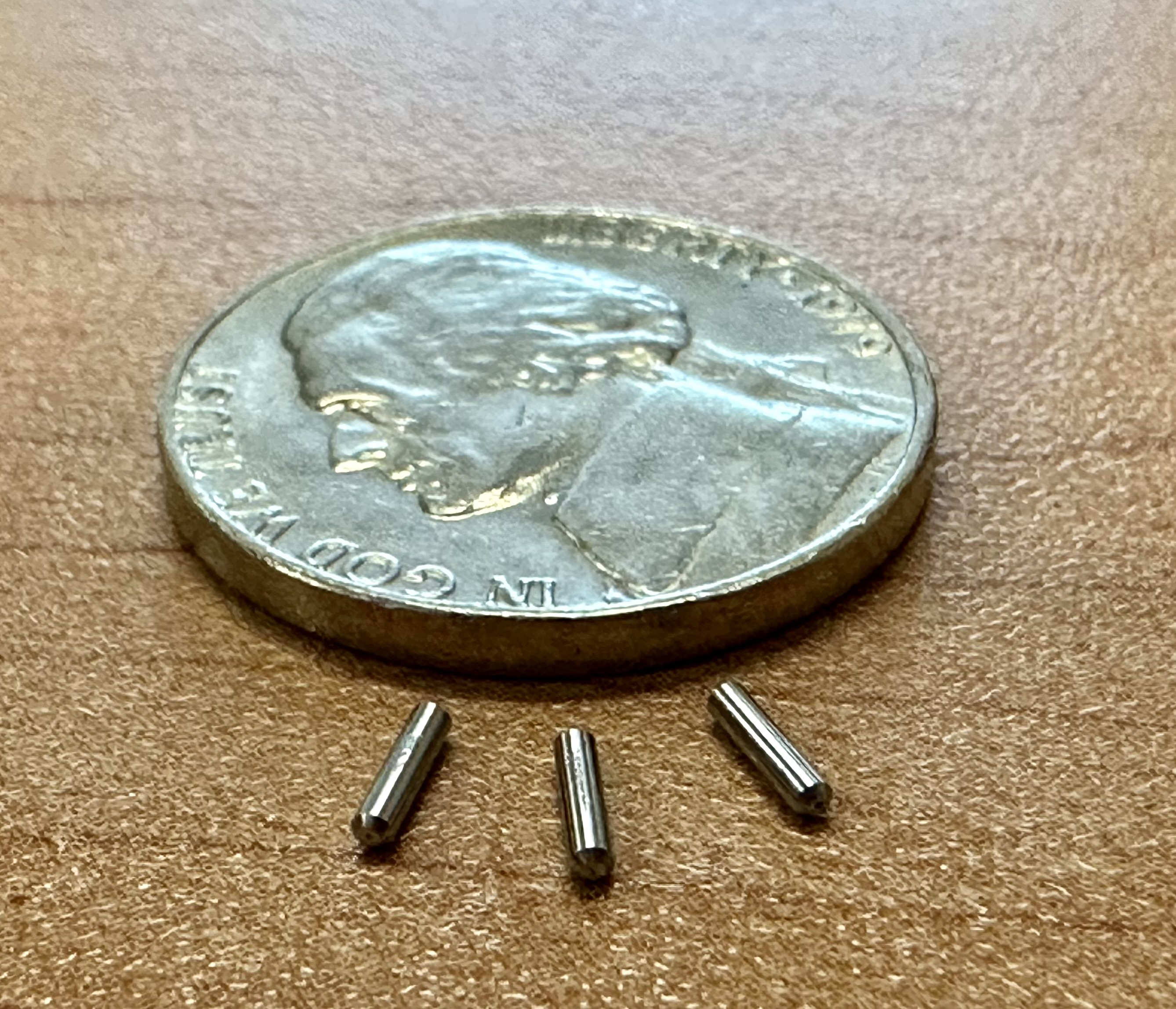

CNC Swiss Machining of Needle Bearing

Hinz Company recently completed a CNC Swiss machining project to manufacture a precision Needle Bearing for the Bearing Industry. Utilizing the advanced Hanwha CNC Swiss-Turn XD20II machine, the Ø.297" Needle Bearing was crafted from Tool Steel, undergoing a heat treatment process to ensure optimal durability. The manufacturing process, with an impressive cycle time of approximately 30 seconds, maintained zero defects such as nicks, dents, or scratches through rigorous quality checks. Weighing around 0.25 pounds, the product met the customer's specifications outlined in the supplied print and 2D CAD drawing. This high-quality Needle Bearing, marked by precision and efficiency, was successfully delivered to the customer in Massachusetts, affirming Hinz Company's commitment to excellence in CNC Swiss machining for critical industrial applications.

| Product Description | Needle Bearing |

| Capabilities Applied/Processes | CNC Swiss |

| Equipment Used to Manufacture Part |

Hanwha CNC Swiss-Turn XD20II |

| Size | Ø.297" |

| Cycle Time |

~30 seconds~ |

| Material | Tool Steel |

| Features |

|

| In process testing performed | Dimensional checks |

| Weight | ~0.25 pounds~ |

| Industry for Use | Bearing Industry |

| Delivery Location | Massachusetts |

| Standards Met | Customer supplied print, 2D CAD Drawing |

| Product Name | Needle bearing |