• Standard 2-station, factory installed 180 degree rotating APC.

• Thermally stable, heavily ribbed stiff cast Meehanite C-Frame construction

• 41HP, high speed 15,000rpm built-in spindle offers high speeds and heavy duty cutting capabilities

• Standard scraper type chip conveyor can be installed on either the right or left-hand side of the machine

• Standard 40-Tool ATC

• High speed processing Kitamura Arumatik-Mi Pro controller offers up to 16x faster processing speeds!

The Hinz Company prides itself with a "Responsive Machining" consultation process in regards to prints submitted. This insures precise accuracy as many times as needed, saving the client money on a per-part basis.

Whether you need precise components for aircraft engines, avionics systems, or other critical aerospace applications, The Hinz Company is your trusted source. Our commitment to excellence in CNC Multi Axis Swiss Turning services, combined with our industry-specific knowledge, positions us as a reliable partner for all your aerospace machining needs. Experience the precision and quality that set us apart in the Aerospace industry with The Hinz Company.

When you require precise components for agricultural machinery, irrigation systems, or other critical applications in the agriculture industry, The Hinz Company is your trusted source. Our dedication to excellence in CNC Multi Axis Swiss Turning services, coupled with our industry-specific expertise, makes us a reliable partner for all your agricultural machining requirements. Discover the accuracy and quality that distinguish us in the Agriculture sector with The Hinz Company.

When it comes to precise components for automotive engines, electronic systems, or other critical automotive applications, look no further than The Hinz Company. We excel in CNC Multi Axis Swiss Turning services and possess specialized knowledge of the automotive industry, making us the dependable partner you need for all your machining requirements. Discover unparalleled precision and quality that sets us apart in the Automotive sector with The Hinz Company.

When it comes to precise components for hydraulic systems, whether it's for aircraft engines, avionics, or other critical applications, The Hinz Company is your trusted source. Our dedication to excellence in CNC Multi Axis Swiss Turning services, along with our specialized knowledge in hydraulics, makes us the reliable partner you need for all your hydraulic machining needs. Experience the unmatched precision and quality that sets us apart in the Hydraulic industry with The Hinz Company.

When it comes to precise components for medical equipment, medical devices, or other critical medical applications, The Hinz Company is your trusted source. Our dedication to excellence in CNC Multi Axis Swiss Turning services, along with our industry-specific knowledge in the medical field, makes us a reliable partner for all your medical machining needs. Experience the precision and quality that set us apart in the Medical industry with The Hinz Company.

What is CNC Vertical Machining?

CNC (Computer Numerical Control) Vertical Machining is a manufacturing process that involves using a CNC machine to create parts and components by removing material from a workpiece. The term "vertical machining" specifically refers to the orientation of the machining spindle within the machine, where the spindle is oriented vertically, perpendicular to the worktable. This setup allows for the cutting tool to move in a vertical direction, primarily along the Z-axis, while the workpiece remains stationary on the table. Here are some key aspects of CNC Vertical Machining:

-

CNC Machine: The CNC machine used for vertical machining is known as a vertical machining center (VMC). VMCs are equipped with a spindle that holds the cutting tool, a worktable for securing the workpiece, and a CNC control system that automates and controls the machining process.

-

Vertical Spindle: The spindle in a VMC is oriented vertically, meaning it moves up and down along the Z-axis. This configuration allows for the precise machining of features on the top surface of the workpiece.

-

Three Axes of Motion: CNC Vertical Machining typically involves three primary axes of motion:

- X-Axis: Horizontal movement of the cutting tool along the length of the worktable.

- Y-Axis: Horizontal movement perpendicular to the X-axis, allowing for lateral tool movement.

- Z-Axis: Vertical movement of the spindle and cutting tool, which controls the depth of the cuts into the workpiece.

-

Precision Machining: VMCs are known for their ability to achieve high levels of precision and accuracy. They can produce parts with tight tolerances and excellent surface finishes.

-

Versatility: CNC Vertical Machining can be used to perform a wide range of machining operations, including milling, drilling, tapping, boring, and contouring. This versatility makes it suitable for manufacturing various components, from simple parts to complex, multi-feature components.

-

Automation: CNC Vertical Machining centers are highly automated, allowing for the efficient and consistent production of parts. The machining process is programmed using computer software, and the CNC control system guides the cutting tool's movement based on the programmed instructions.

-

Suitable Materials: CNC Vertical Machining can be applied to a variety of materials, including metals (such as steel, aluminum, and titanium), plastics, and composites.

-

Tool Changes: VMCs often have automatic tool changers that can switch between different cutting tools during the machining process, allowing for a wide range of operations to be performed in a single setup.

CNC Vertical Machining is commonly used in industries such as aerospace, automotive, medical device manufacturing, and general machining, where precision and efficiency are essential. It is ideal for creating complex parts and components with a high degree of accuracy, making it a cornerstone of modern manufacturing processes.

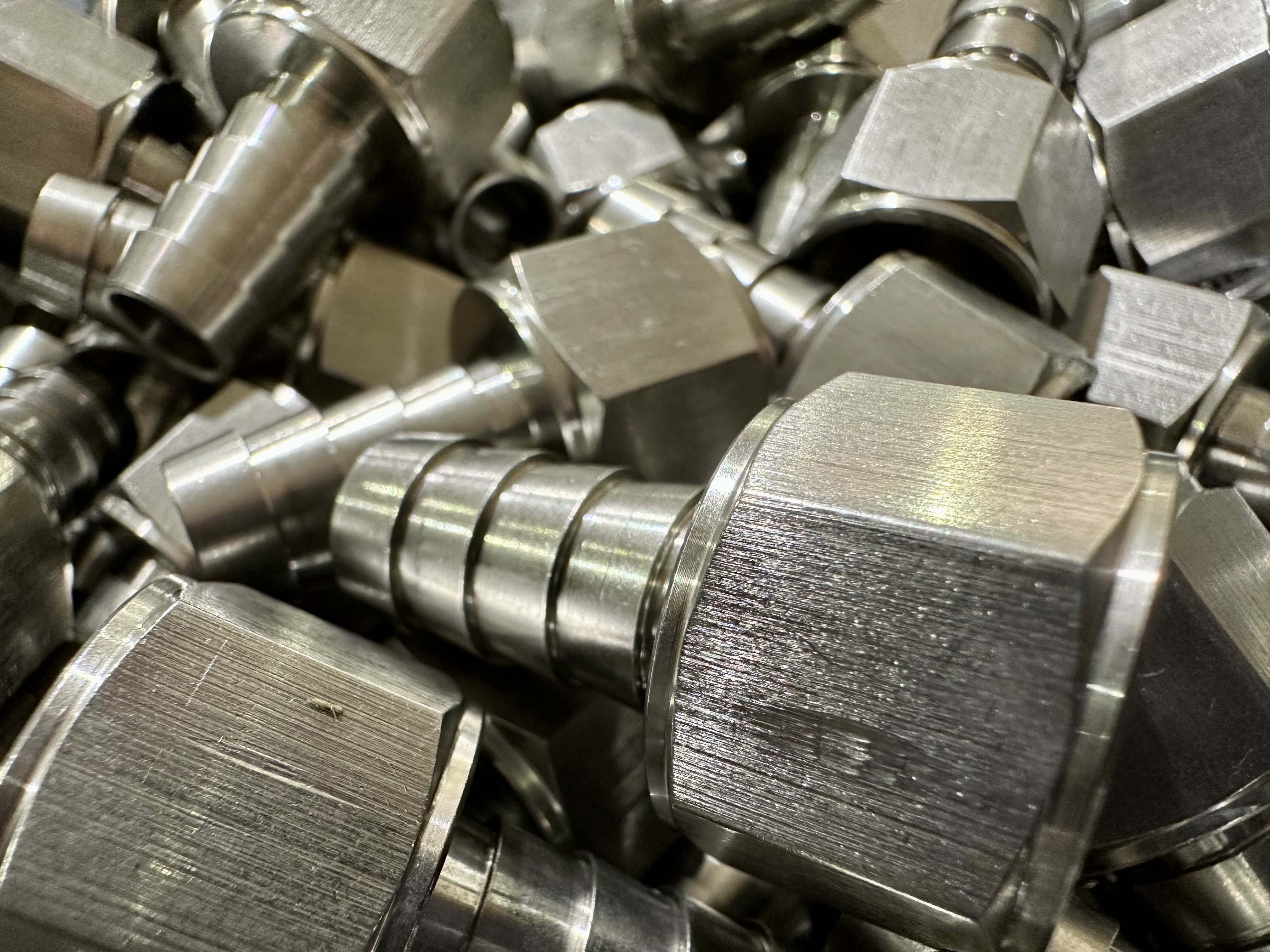

Custom Machined Parts

By seamlessly integrating advanced CNC machining technologies, The Hinz Company positions itself at the forefront precision engineering of custom machines parts. Their dedication to innovation is reflected in their state-of-the-art manufacturing processes, which enable the production of intricate custom machined parts with exceptional accuracy and efficiency. The company's responsive service is a cornerstone of their operations, ensuring that clients' unique specifications and requirements are not only met but exceeded. This commitment to tailored solutions has solidified enduring relationships with clients, as The Hinz Company becomes a trusted partner in the realization of superior products. Moreover, their competitive cost structure underscores their commitment to delivering value, making them an industry leader in the realm of custom machined parts.

Looking for High Volume Swiss CNC Parts?

Hinz Company specializes in the production of high-volume Swiss CNC machined parts, leveraging advanced Swiss machining technology for precision manufacturing. Their expertise caters to diverse industries, including medical, electronics, aerospace, automotive, and watchmaking. Hinz Company excels in crafting intricate components like surgical instruments, electronic connectors, aerospace hardware, automotive parts, and precision watch components. With a focus on efficiency, their employment of simultaneous machining on CNC lathes ensures faster production times, meeting the demands of mass production. Hinz Company's commitment to versatility is evident in their ability to work with various materials, underscoring their flexibility in addressing specific manufacturing needs and consistently delivering high-precision CNC parts.

Responsive Machining

The Hinz Company places a strong emphasis on its distinctive "Responsive Machining" consultation process, a cornerstone of its commitment to delivering exceptional precision and accuracy in every project. At the core of this approach is the thorough examination of prints submitted by clients. The company's dedication to responsiveness ensures that each project undergoes a meticulous review, guaranteeing that all specifications are thoroughly understood and incorporated into the machining process.

This commitment to a "Responsive Machining" philosophy is designed to benefit clients by not only meeting but exceeding their expectations. The iterative nature of the consultation process allows for adjustments and refinements to be made as many times as necessary, ensuring that the final product aligns precisely with the client's specifications. This iterative refinement not only enhances the accuracy of the machined parts but also contributes to substantial cost savings on a per-part basis.

By actively engaging with clients throughout the machining consultation process, The Hinz Company establishes a collaborative environment where feedback is welcomed, and adjustments are seamlessly integrated. This approach not only streamlines the production process but also minimizes the likelihood of errors or misunderstandings, ultimately contributing to a more efficient and cost-effective outcome.

In essence, The Hinz Company's commitment to "Responsive Machining" goes beyond the conventional service model. It reflects a dedication to client satisfaction, cost-effectiveness, and a relentless pursuit of precision in every aspect of the machining process. Clients can trust that their projects are in capable hands, where the combination of expertise, responsiveness, and attention to detail results in the delivery of high-quality, accurate machined parts.