Hinz Quality Mission: To provide continuous improvement and responsive solutions for outsourced machined parts. Use state of the art technologies and be creative andpassionate in the execution of customer needs.

The following Equipment List will better display our current capabilities. Hopefully our extensive list of equipment can assist you in lowering your costs of purchased machine parts while at the same time improve the service you are currently receiving.

Our equipment offers a vast range of capabilities to serve you:

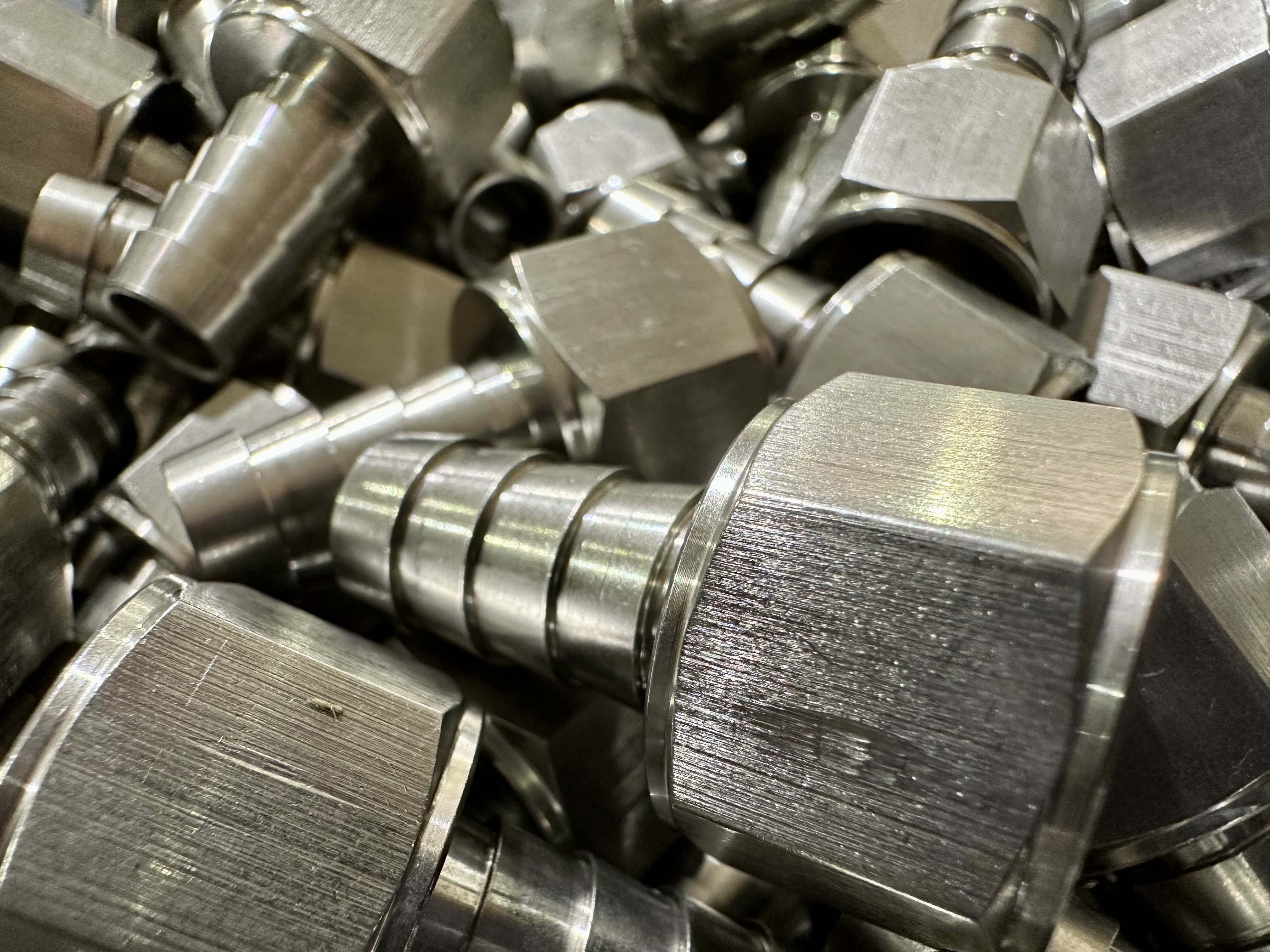

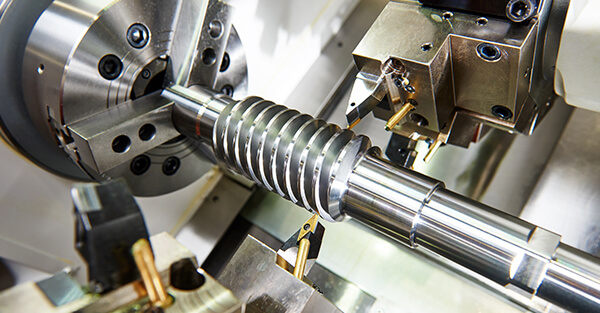

- Multi-task & sub-spindle CNC Turning up to 2-5/8” round (8” chucking) with up to eight controllable axis with two robotic loading systems.

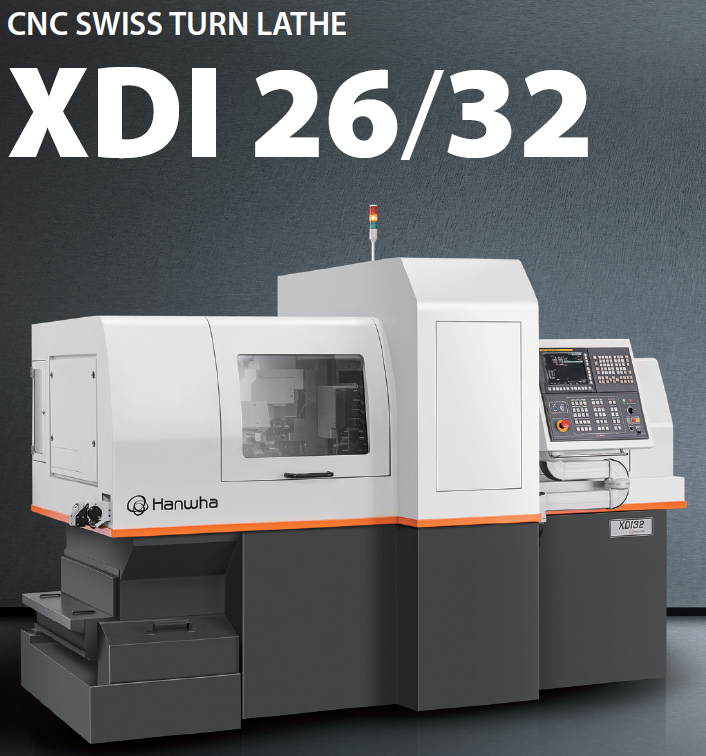

- CNC Swiss turning to 1-1/2” round with up to eight controllable axis.

- CNC Vertical machining with 25” X 17” turntable style pallets.

Our modern 41,000sf manufacturing facility in The Franklin Business Park features a quality assurance room utilizing the latest technology for inspecting parts, an air conditioned plant, and easy access to I94.

Our competitive advantage to you is clear—Hinz provides parts machined with the minimal amount of labor added thereby reducing your ultimate costs.

We ship on a just in time basis and welcome your emergency needs. In addition, Hinz would be delighted to estimate future engineered parts and prototype them as well.